The indirect contact dryer is suitable for drying or cooling pastes, particles and powders in a slurry state. The special stirring blade features high heat transferring efficiency, providing a self-cleaning function.

Hollow chock shaped blades are fitted on the hollow shaft where the heat media flows through the blade. The temperature range of the blade dryer is -40 ℃ to 320 ℃.

The large heating area in the drying unit dries the material very fast and it is suitable for a wide variety of different industrial applications.

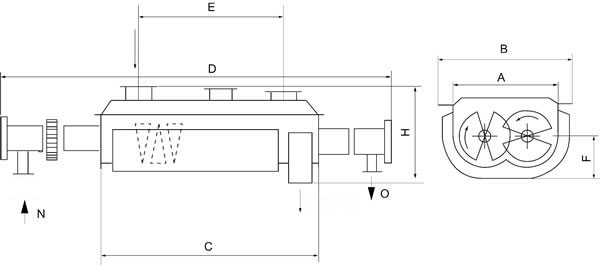

| Specification | |||||||||||

| heat transferring area m2 | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| effective volume m3 | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| range of rotating speed r.m.p | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| power kw | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| width of vessel mm | 306 | 584 | 762 | 940 | 1118 | 1296 | 1474 | 1652 | 1828 | 2032 | 2210 |

| total width mm | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| length of vessel mm | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| total length mm | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| distance of material inlet & outlet mm | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| height of center mm | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| total height mm | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| steam inlet "n" ( inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

| water outlet "o" (inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More