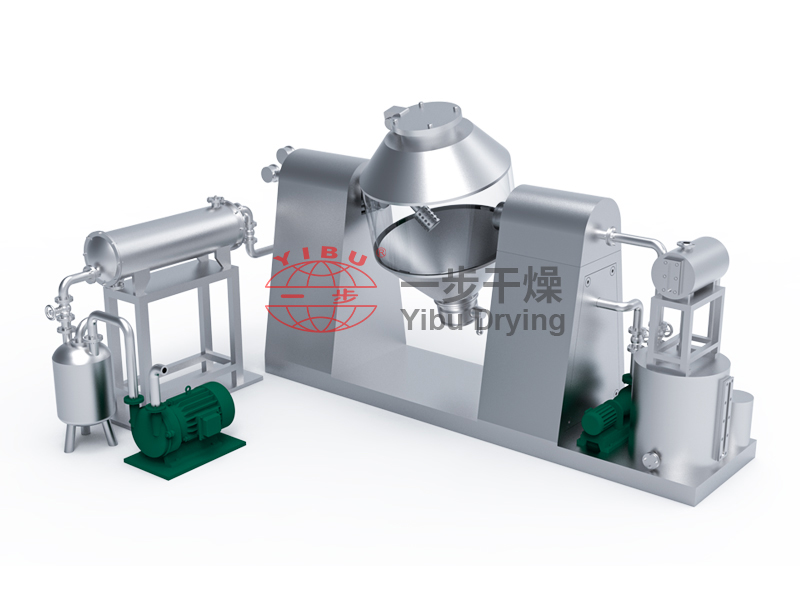

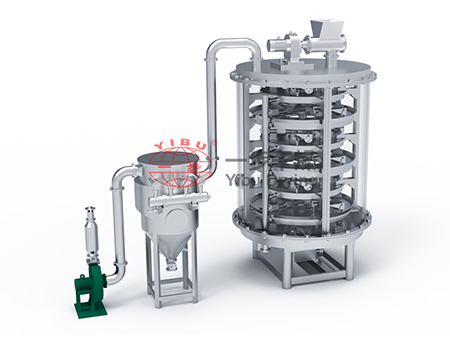

The equipment consists of a tubular external heater, vacuum evaporator and an auxiliary device. It features quick heating time, rapid evaporation and can protect thermosensitive materials..

Our team of experts is at your disposal to find the best solution!

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.