The GFG series fluid bed dryer uses purified and heated air introduced from the bottom of the chamber with a suction fan. Fluidization of raw materials is possible through stirring and negative pressure within the chamber. Moisture is then quickly evaporated and removed for high quality material drying.

| Items | Specification | |||||||||

| Production capacity | kg | 60 | 100 | 120 | 150 | 200 | 300 | 500 | 1000 | |

| fan | velocity | m3/h | 2361 | 3488 | 4000 | 4901 | 6032 | 7800 | 10800 | 15000 |

| air pressure | mmH2O | 594 | 533 | 533 | 679 | 787 | 950 | 950 | 1200 | |

| power | kw | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 | 75 | |

| Power of agitator | kw | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 1.5 | 1.5 | 2.2 | |

| mixing speed | rpm | 11 | ||||||||

| Air consumption | kg/h | 141 | 170 | 170 | 240 | 282 | 366 | 451 | 800 | |

| Operation time | min | 15-30 (depends on raw materials) | ||||||||

| Height | mm | 2700 | 2900 | 2900 | 2900 | 3300 | 3800 | 4200 | 5800 | |

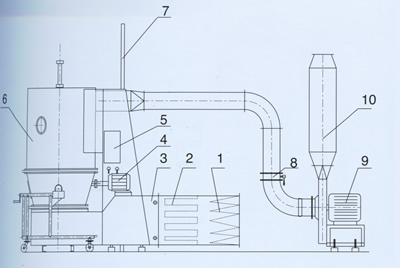

1. Filter

2. Sub-high efficiency filter

3. Heater

4. Motor

5. Control cabinet

6. Dust collector

7. Separated wall

8. Air door

9. Fan

10. Silencer

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More