The series fluid bed dryer is used for drying and cooling of powder or granular materials such as citric acid, monosodium glutamate and many others.

| Specification | Fluid bed | Size | Power of motor (kw) | Weight (kg) | |||

| W | L | A | B | C | |||

| 3×30 | 300 | 3000 | 3505 | 450 | 1050 | 0.37×2 | 1240 |

| 3×45 | 300 | 4500 | 5005 | 450 | 1050 | 0.75×2 | 1570 |

| 6×45 | 600 | 4500 | 5005 | 750 | 1350 | 1.1×2 | 1967 |

| 6×60 | 600 | 6000 | 6510 | 750 | 1350 | 1.1×2 | 2743 |

| 6×75 | 600 | 7500 | 8010 | 750 | 1750 | 1.5×2 | 2886 |

| 9×60 | 900 | 6000 | 6510 | 1050 | 1750 | 1.5×2 | 3540 |

| 9×75 | 900 | 7500 | 8010 | 1050 | 1750 | 2.2×2 | 4219 |

| 12×75 | 1200 | 7500 | 8010 | 1400 | 2200 | 3×2 | 5223 |

| 15×75 | 1500 | 7500 | 8010 | 1700 | 2500 | 4×2 | 6426 |

| 18×80 | 1800 | 8000 | 8520 | 2000 | 2800 | 4×2 | 8600 |

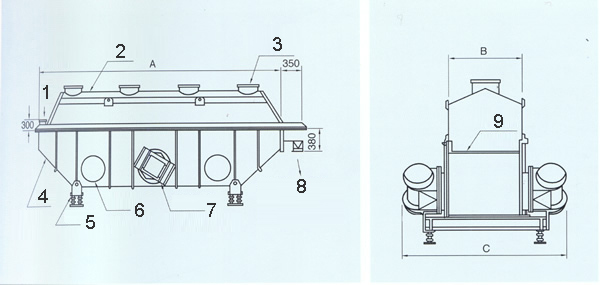

1. Feeding inlet

2. Upper cover

3. Air outlet

4. Main body

5. Anti-vibration spring

6. Air inlet

7. Vibration motor

8. Discharge port

9. Fluid Bed

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More