The series fluid bed dryer is a common piece of equipment found in pharmaceutical applications. It consists of an air filter, fluid bed and cyclone separator. There are two kinds of operation for this machine, continuous and intermittent.

This equipment is used for the drying processes of various medicines, grain processing and many other applications. The ideal material diameter range is 0.5-3mm.

| Model/items | Drying capacity kg/h | Power of fan | Air pressure /Pa | Air amount m3/h | Temperature of inlet air /℃ | Max consumption /J | Way to feed materials |

| 10-15 | 7.5 | 5.5×103 | 1500 | 60-200 | 2.0×108 | 1. unloading valve 2. Pneumatic conveying |

|

| 20-25 | 11 | 5.8×103 | 2000 | 60-200 | 2.6×108 | ||

| 30-40 | 15 | 7.1×103 | 3850 | 60-200 | 5.2×108 | ||

| 50-80 | 30 | 8.5×103 | 7000 | 60-200 | 1.04×109 |

Notes: The drying capacity is measured under such conditions: the primary moisture of crystal of plum is 20% and its final moisture is 5% and the temperature of air inlet is 130℃. The Drying capacity of other raw materials depends on the actual condition. While choosing models, please note that: Model A should be equipped with cyclone separator; Model B with internal dust collector; Model C with cyclone separator and dust collector.

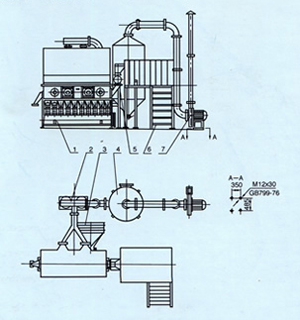

1. Main machine

2. Cyclone separator

3. Heater

4. Dust collector

5. Feeder

6. Operating platform

7. Fan

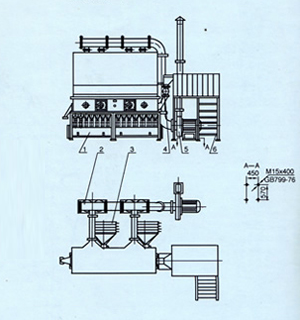

1. Main machine

2. Cyclone separator

3. Heater

4. Feeder

5. Fan

6. Operating platform

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More