Project category: Food industry

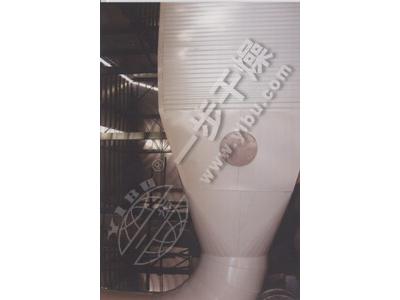

Selected product: DG series air stream dryer for starch

Equipment description:

The DG series air stream dryer operates with starch which is shaped like a filter cake. Starch is fed into a lift where it will be broken up into fine particles. The lift rotates at high speed to generate wind energy, which enables the fine particles to be transferred to a drying tube. These fine particles come into contact with hot air. They are suspended in the airflow due to its high speed in the drying tube. It takes only several seconds to complete the drying of materials, because of a large solid-gas heat transfer area as well as a high heat-transfer coefficient.

Dry starch is conveyed through a cyclone separator and moves to a starch sieve. After filtration, the material is required to enter into a silo. A packaging machine is available for packing the starch into bags. Then a belt conveyor is used to send the starch to a warehouse. After the drying process, the exhaust gas with high content of moisture is discharged using a fan.

Customers we have served:

(1) Gansu Lintao Tengsheng Company

(2) Jiangyan Starch Factory

(3) Hubei Wuhan Starch Factory

(4) Beijing Ruisikang Food Technology (and Engineering) Co., Ltd.

(5) Heilongjiang China Essence Potato Industry Co., Ltd.

(6) Shanxi Pingshun Xinyuan Green Industry Co., Ltd.

(7) Inner Mongolia Siziwang Banner Runkai Agriculture Development Co., Ltd.

(8) Ghana, Africa

Our team of experts is at your disposal to find the best solution!

We offer comprehensive service and support for all of our drying equipment starting even before the customer makes a purchase.

Read More