| Parameters | 5 | 25 | 50 | 100 | 150 | 200 | |

| Amount of evaporation Kg/h | △ t=150 ℃ -90 ℃ | 1.5 | 7.5 | 15 | 30 | 45 | 60 |

| △ t=200 ℃ -100 ℃ | 2.5 | 12.5 | 25 | 50 | 75 | 100 | |

| △ t=250 ℃ -100 ℃ | 3.75 | 18.75 | 37.5 | 75 | 112.5 | 150 | |

| △ t=300 ℃ -100 ℃ | 5 | 25 | 50 | 100 | 150 | 200 | |

| △ t=350 ℃ -110 ℃ | 6 | 30 | 60 | 120 | 200 | 240 | |

| Pressure of air M3/min | 0.9 | 0.9 | 1.1 | 1.5 | 2.7 | 3.4 | |

| Pressure of air Mpa | 0.4 | 0.6 | 0.7 | ||||

| Heat resource | electricity, electricity + steam, coal(oil) combustion furnace | ||||||

| Consumption of heat 104Kcal/h | 1 | 5 | 10 | 20 | 30 | 40 | |

| Power Kw | 0.75 | 4 | 7.5 | 11 | 15 | 18.5 | |

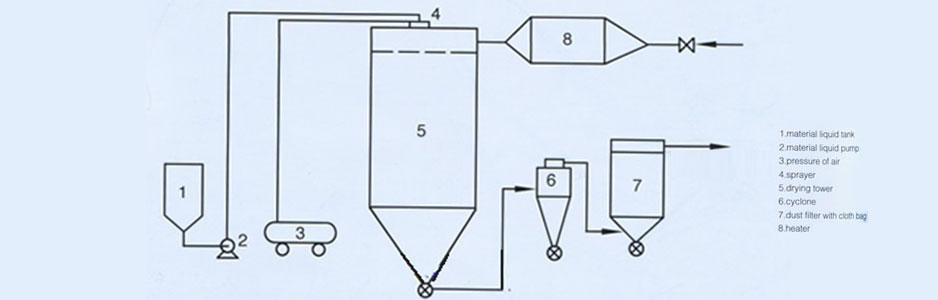

The hot air spray dryer introduces filtered, heated air into the drying tower where the material is atomized into a fine mist. This quickly evaporates the moisture from the mixture and the powder left behind is discharged and collected.

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More